AR-15 style rifles are quickly becoming the new standard for a rifle. Everyone has one or wants one. We all know what they are and how they work… sort of. The AR is a unique system that takes a little different mindset, equipment, and operation than most other rifles. Here are 10 things you probably don’t know about your AR:

- Most Malfunctions Are User induced

Most people create their own problems when it comes to the AR rifle. Almost every malfunction can be traced to the user doing something wrong to the rifle that caused the gun to malfunction. Then, if the user hasn’t been trained to clear malfunctions, they make the problem worse! I see it all the time on the range and at classes. Keep reading for the most common mistakes I see people make when running their ARs.

- How to Properly Sling Shot the Bolt to Load a Round

You have to pull the charging handle all the way back until it stops and then let it go to properly chamber a round. If you try to go to fast you may short stroke the gun and there will not be enough energy for the bolt to strip off the top round in the magazine, feed it into the chamber, and lock up correctly.

The same thing also happens when users want to help the rifle go into battery by slowly letting the charging handle go back into the gun. That isn’t how the rifle is designed to operate. It is designed to run fast and hard. Just look at how fast that bolt goes back and forth when the rifle is being fired. That is how the rifle was designed to work.

I’m convinced guns have a memory. When you treat them badly (especially when chambering the first round) they remember and malfunction in the next couple rounds. I know it doesn’t make sense but I’ve seen it on the range time and time again with newer shooters. They don’t operate the gun correctly to chamber that first round and the second round they fire out of that magazine malfunctions. Can’t explain it, but know how to fix it. Sling shot your rifle correctly to load that first round and it will get rid of most of these problems!

- Correctly Insert a Magazine

Tap/Tug is the way to insert a magazine into the mag well if you want the gun to run correctly. You push the magazine in hard as far as it will go (that’s the tap), then while still holding onto the magazine (you don’t let go of it), you pull on the magazine to make sure it doesn’t come out.

With most AR’s, you can push a magazine up into the mag well and it will stop there. That doesn’t mean the magazine release has caught the mag correctly, it just means it isn’t falling out of the gun. If you don’t get the magazine in all the way, what generally happens is the gun either doesn’t pick up a round at all and nothing goes into the chamber, or the gun will chamber the first round and then the magazine will fall out under recoil. And that just looks really stupid.

The other thing I see people do all the time, is put the magazine into the gun and then start smacking the crap out of it trying to shove it further into the gun. Remember a 5.56mm round is rather skinny, small, and light weight. If you start hitting the bottom of the magazine with all your might, those rounds are going to move around inside the magazine and so will the follower. If they move and then don’t move back to line up correctly, the gun will malfunction somewhere in that magazine and it was your fault.

When doing a bolt open reload and you start smacking the bottom of the magazine it could be worse. You can actually get two or three rounds to come out of the top of the magazine and into the ejection area of the gun. If you don’t watch, you will release the bolt and the bolt will try and shove everything into the chamber. One at a time is the only way to feed your AR!

- Filling Mags too Far

For the love of all that is holy, only 28 rounds go into a 30-round AR magazine. I know some times you can get away with 29 and sometimes even 30. I don’t care what the manufacturer says about the round count on an AR mag. Fill it to 28 rounds!

With 28 rounds in the magazine, you’ll never have a problem. I’ve seen the newest generation Pmags (and just about everything else) fail to work with 30 rounds in them. I’ve seen a magazine that would work fine on one gun with 30 rounds in it not work with another gun.

What happens is you compress the magazine spring so far that the top rounds don’t want to come out. Then, when you put it into the gun, the bolt doesn’t have enough energy to drive the top round out of the magazine and into the chamber. You get the round to come halfway out of the mag and the bolt only goes half way home. So you pull on the charging handle and let it go again. The bolt comes all the way to the rear and tries to pick up a second round and shove it into the gun. If you are lucky that’s as far as it goes, you pull the magazine out and fix the problem. Normally, those two extra rounds the bolt was playing with fall to the ground and are lost forever because now they are bent up. So you lose the two rounds you thought you were gaining.

With 30 rounds in a magazine you may not even get that far. People smack the bottom of the mag to insert it (see #3) to get it to seat correctly because the magazine spring is already compressed all the way and when you put a full magazine into a rifle with the bolt forward that spring needs to compress a little further so there is room for the bolt to work. Since the magazine spring won’t compress any further, the magazine won’t go all the way into the gun and lock into place. So you try beating it into submission and cause more problems (this goes back to #1)

- Where to put lubrication on the gun

Most people just want to throw oil all over the bolt carrier group and some want to even use grease on the buffer spring inside the tube. Don’t do that! Don’t put oil into the buffer tube. Yes, it will quiet the spring down a little, but you will still hear it! All that oil or grease will just attract dust and dirt into your spring and slow down your bolt cycling inside the tube. That will cause your gun to malfunction and create one hell of a mess for you to clean up.

On the bolt carrier group, towards the front, you will see two rails on the bottom (they will be shinny on an older rifle) and two rails on top. One on each side of the carrier key (the little periscope, yes that’s what the Marine Corps called it, looking thing on top). Lubrication goes on those four rails, not all over the carrier. Oil attracts dirt and dirt is what will make your rifle malfunction. You need just enough oil that the rails look shiny from being wet.

Inside the carrier around the bolt you need a little oil. Pull the bolt out and look at it outside of the gun. Between the gas rings and the hole where the cam pin goes, is another shiny spot. It’s a ring raised around the entire bolt. That is the part that touches inside your bolt carrier inside. That is where oil is needed. Yes, you can fake the funk by putting a drop of oil inside the gas holes when the entire rifle is together, but what really needs to be lubricated is that little spot.

Nothing else on your AR requires oil to work. I like putting oil on the metal parts (just a little) to keep the rust away, but that is not required for the rifle to cycle when being fired.

- The More Stuff on Your Rifle, the Less Reliable it is

Everyone wants the new super cool thing to put on their rifle. It started with quad rails and putting stuff on the rails. It went from a NVD (Night Vision Device) Laser to a flash light to fore grips to multiple flashlights and hand stops and pressure switches and then to visible lasers and just keeps going. The more and more stuff, the heavier the rifle gets.

Now that doesn’t seem cool enough so we want to put more stuff on and in our rifles. Since nothing else fits on the rails, now we want to change the inside of our rifles. JP is making some ground breaking stuff like super short stocks that require a different buffer tube, spring, buffer and bolt carrier group. There is even a folding stock on the market, smaller barrels, and anything you can think of. We want adjustable gas systems because sometimes we think we will run the rifle suppressed and sometimes we won’t.

Companies make all this extra crap because we buy it, not because it makes the rifle better. If enough people pay for it, companies will make anything.

The more crap you put on or into your rifle, the less reliable it becomes. The 20-inch, full stock, rifle length gas system is probably the most reliable of all. Next would be the 16-inch, adjustable stock, carbine length gas system rifles. The more we mess with this system to “make it better” without thinking of what we are doing and why, the less reliable the rifle becomes.

Granted most people won’t need or ever use the full capabilities of the rifle (hopefully including me) but it’s something most people don’t understand or don’t want to acknowledge. Just know that everything you do to alter the rifle it makes it less reliable and not more. Watch how many things you stack onto the system. Sooner or later it will fail you if you keep stacking stuff. And Murphy’s Law says it will happen at the worst time.

- There are springs everywhere

Everything holds a spring and detent in an AR. You can’t take off or replace anything without worrying about a spring disappearing. Even the simplest thing like a grip holds a spring and detent.

If you start taking things off your rifle, look at a diagram first or at least watch out for the spring and detent that is being held in place.

- You Should Have a Parts Kit

The springs I talked about in #7 are small and hard to find. Sooner or later you will lose one. As an individual spring they are expensive. I’ve seen spring kits for as little as $10 dollars at gun shows and charged as much as $5 for a single spring out of the kit to get someone’s rifle running again. That person was happy to pay the $5 after looking everywhere for the spring and finding out his rifle won’t work without it.

If you see an extra spring kit and don’t have one, pick it up. Sooner or later it will pay big dividends. If not for you, you can be the hero of your next shoot when someone loses one at the range. I normally keep a kit in my bag when I’m shooting rifle. It won’t hurt you and could save you.

I just ordered another one here from LAPoliceGear.com for $5!

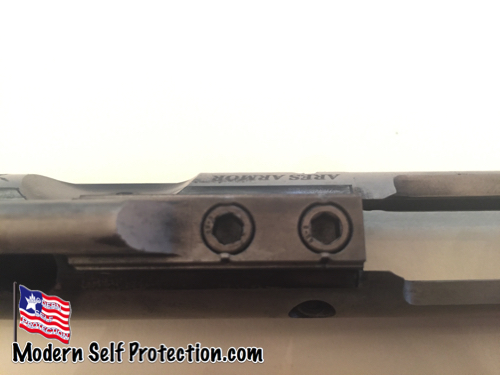

- Staked Parts

There are two parts on an AR that should be staked. Staking is a simple process where you punch some of the metal from one part into the nut or bolt that is holding the two parts together. It keeps the nut and bolts from backing out during firing.

I know it doesn’t feel like it, but an AR vibrates like crazy when being fired. All you hear is the spring twanging in your ear, but the entire rifle might as well be a tuning fork it vibrates so much.

That vibration can cause your carrier key bolts to walk out. When that happens your rifle will not run because there is no longer a gas seal for the piston to work and make your bolt unlock so the carrier group can move to the rear and cycle the rifle.

The other thing that happens is the carrier key comes off and locks up the rifle. This is a horrible problem to have and sometimes involves a hammer and other tools. Not fun. So check your key and make sure it’s staked.

I haven’t seen this problem in a long time. Most manufactures have figured this out and found that this is an easy and necessary part of the manufacturing process so they don’t piss of their end users.

The other stake point that I see missed all the time and see the problem on the range with them is staking the castle nut on the buffer tube. This nut holds the buffer tube to the rifle and that holds the buttstock so you can shoulder the rifle and fire it.

Again your rifle is like a tuning fork and vibrating like crazy. If you don’t stake the castle nut sooner or later it will loosen. If you are lucky you will catch the problem before you lose a part. Normally the first thing you will notice is that the stock will rotate left and right on the back or the rifle. Your castle nut is loose and that means so is the rear plate. That plate is holding (you guessed it #7) a spring and detent. If you rotate the stock one full turn out you will lose another spring and detent.

All of this sucks and is extremely embarrassing. If your castle nut isn’t staked, take a punch and a hammer and take care of some business. It will save you tons of work, parts, money, and headache in the long run.

- Wear in

A new AR takes very little wear in time or break in. I like to go a little heavy on a new gun the first range trip or two just to be kind to it.

If you have a precision gun read the manufacturers barrel break in procedure and do that. If you aren’t running a super accurate gun I don’t worry about the barrel really breaking in. The first range trip I won’t run the gun really hard and will make sure I clean it really well when I get home. Just so we are on the same page, running the gun hard means getting it really hot. If you can’t touch the barrel without burning your finger, you are running the gun pretty hard. If you have a problem holding the handguard because the barrel is so hot that it’s burning your hand through the guard, you are running your gun really hard. When it’s that hot you are probably doing small amounts of damage to your barrel and shortening it’s life. But don’t freak out if you have done that, it’s not that much and you probably will never notice a difference unless you do it all the time.

For parts break in, I just add extra oil to the bolt and bolt carrier group rails.

There is one unusual place I put oil on a new rifle and that’s on the charging handle where it runs inside the upper receiver. A new gun’s upper receiver and charging handle are generally bone dry. They have no oil on them because they don’t really need it. Your bolt will have a little oil on it because they are steel and the will rust if they are totally dry. The receiver and charging handle are aluminum and won’t rust so manufacturers will not bother to put oil on them.

The dry charging handle isn’t that big a deal but drives me crazy. If you don’t put any oil on it, you’ll find that it gets harder and harder to pull and the finish will start rubbing off of the charging handle after the first range session.

It just looks bad and you start wondering if there is a problem with your new rifle. After a couple range sessions, excess oil will come off the bolt carrier and you won’t have any problems, but it’s just easier to put a couple drops on the handle and avoid the problem.

Conclusion

That’s all 10! Bet there was one you didn’t know about. If you knew all of them, then it was a good review. Sometimes we all forget things we should know and do from time to time.

If nothing else, go look at your rifles and make sure those two places are staked in the right spot.

Stay Safe,

Ben

When I was in the Army bootcamp back in 81 they had us smack the magazines on our steel pots to move the rounds to the back of the magazine. Don’t know if it helped but you do what the DI tells you to do. Became a habit pretty quick. On a funny note last year I was doing some shooting and not thinking and smacked a metal GI magazine on my head before seating the mag. Needless to say I started paying attention.

Haha! That’s awesome how those things get so programed into us! Yes I still smack the mag as I fill it with ammo…. But normally on the back of my hand or the bench. I don’t use me head anymore.

Thanks very much for this very useful and well-written article. There are lots of myths, rumors, and fables out there concerning AR-15 maintenance. Thanks for cutting thru the “fog” and getting right to the essentials.

Yeah, about #5…. I have just completed the build of my first AR, nothing exotic, and after watching Larry Potterfield I coated the buffer spring in grease

https://youtu.be/pcko0UlvQxQ , so I’ve already induced the gunk. I guess I need to get a handful of shop rags and a screwdriver and start swabbing it out.

I finished it late last Friday night, family came in for the weekend, and frustratingly I haven’t fired it yet. I guess I’ll clean it out before this weekend.

I appreciate the podcast,

Richard